As a forefront leader in high-tech construction services, AM Technical Solutions (AM) was recently awarded project scope to deliver top-tier cleanroom build and performance services for a global semiconductor manufacturing company.

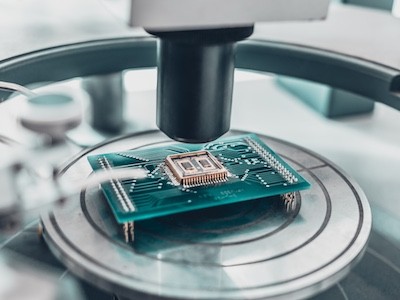

Our client recently expanded its U.S. semiconductor capabilities to enhance the production of sputtering targets for semiconductors. This component is essential for the manufacturing process, as the purity of sputtering targets must be maintained to support the performance of semiconductor devices.

Our team is prepared to deliver cleanroom solutions that will support the quality of production in their facility. We will operate with a “first time right” approach to ensure the manufacturing facility can operate according to the required specifications.

Project Scope to Support Sputtering Targets for Semiconductors

Our team of high-tech construction professionals has been entrusted with a comprehensive project scope. We will aim to uphold the highest standards of cleanroom performance when delivering the following scope:

- Perform Leak Tests on HEPA Filters: To maintain an ultra-clean environment crucial for semiconductor manufacturing, we will rigorously test each HEPA filter for leaks, ensuring optimal filtration and contamination control.

- Conduct Airflow Vormetric Readings on Filters: We will optimize the airflow through precise vormetric readings, playing a pivotal role in contamination prevention and ensuring a uniform cleanroom environment.

- Execute Air Cleanliness Classification: We will ensure the rooms meet the stringent particle count requirements of semiconductor production, particularly in the fabrication of sputtering targets.

- Execute Differential Room Pressure Survey: Our survey will validate that the differential pressure between the cleanroom and adjacent areas is accurately maintained, mitigating the risk of cross-contamination.

- Perform Airflow Directional Test and Visualization: Our team will ensure that the airflow direction adheres to the required standards, safeguarding the cleanroom’s integrity.

- Monitor Temperature and Relative Humidity: Precise environmental control is vital in a cleanroom setting. Our team will implement advanced monitoring to maintain the exact conditions necessary for optimal semiconductor manufacturing.

- Report on Outcomes of Project Scope: We will provide detailed reports on all project scope. Our team will offer valuable insights and recommendations for continuous improvement and adherence to the highest industry standards.

Our Cleanroom Build and Performance team is fully equipped to provide solutions at each project stage. Our team combines technical prowess, innovative solutions, and an in-depth understanding of our clients’ unique requirements to deliver exceptional results.

“We are proud to be a key player in advancing the semiconductor industry. And, we understand the importance of cleanroom quality to support the manufacturing of sputtering targets for semiconductors,” says Dan Codi, AM Chief Operating Officer. “Our services will be integral to ensuring that our semiconductor client’s new facility operates at the highest levels of cleanliness and efficiency.”

– Find out more about our capabilities to support semiconductor construction projects.

– View our portfolio of award-winning semiconductor construction projects.

– Does your semiconductor company need cleanroom build and performance support? Learn more about utilizing our high-tech construction services. Contact us today to discuss your project requirements.