From the CII Modularization Community of Business Advancement.

The future execution strategy for industrial capital projects is moving towards maximizing the efforts to identify and implement the optimal level of modularization on all projects. As discussed in the McKinsey & Company article [1], “How construction can emerge stronger after coronavirus,” the COVID-19 pandemic is accelerating some long-term trends for construction which include offsite construction or modularization. As stated in the article:

“Increase in offsite construction. Building in controlled environments makes even more sense in a world that requires close management of the movement and interaction of workforces. Such rationale further strengthens the case for offsite construction, beyond the existing quality and speed benefits. In fact, we expect to see contractors gradually push fabrication offsite and manufacturers expand their range of prefabricated subassemblies.” [1]

However, the industry has limited knowledge on what needs to be done to implement modularization successfully. As such, companies are implementing modularization poorly and too late on a project and failing to achieve maximum cost and schedule reductions.

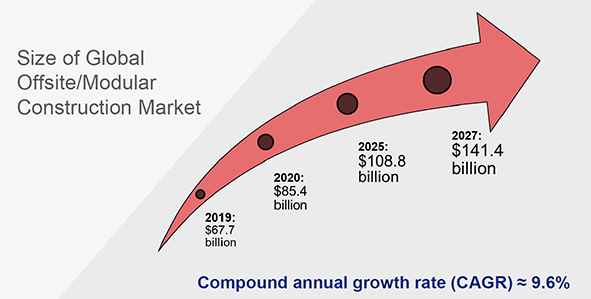

At the 2021 CII-Curt annual conference in Orlando, RT-371 presented “Getting Ready for 2030: A People, Process, and Technology Roadmap for Offsite Construction.” This research detailed what is required to ensure the workforce in 2030 has the skills and resources to move to offsite construction. Their presentation indicates that there will be an annual growth rate of 9.6% in the offsite construction market.

The main areas the research team focused on were people, processes, and technology. The following were some of the main pain points to move to offsite construction that needs to be improved [2]:

- Immature processes, inconsistent implementation of offsite construction

- Lack of detailed offsite design solutions

- Lack of properly developed targeted offsite workforce training

- Lack of integration, collaboration with key stakeholders on offsite projects

The industry needs to change or advance in the modular industrial project planning, design, and execution (and its advanced planning, Lean, and other early coordination requirements) to take full advantage of the reduced capital costs and the many other benefits modularization can bring to a project or program. With the increased industry emphasis on improved safety, reducing energy consumption, providing a circular economy with reduced waste, improved safety, and higher quality, the answer to capital projects is the reliance on the combination of modularization, standardization, lean and unique efforts like RT-373’s MCPI (Modular Chemical Process Intensification). Industry’s need for more capital-efficient projects is increasing and will be a focus for companies in the future.

A gap has been found between the RT-283 content that was published in 2013 to what is currently required for the successful execution of a modular project. By addressing this industrial modularization knowledge and implementation gap, CII has the opportunity to take the lead in a collective initiative that can impact the industry on multiple levels, from the current industrial productivity issues to the newer green initiatives, including the Environmental, Social, and Corporate Governance (ESG) criteria.

This initiative can impact the industry through an innovative clear, concise, and complete industrial modularization implementation by developing an advanced planning guideline. It will also address any barriers that are impacting the successful implementation of industrial modularization on projects.

Recently, the Modularization CBA has formed a Modularization Advanced Planning working group that is in the process of developing the framework for an advanced planning guide for industrial modularization. This framework will be the starting point for a research project that involves developing the complete advanced planning execution guide for industrial projects, including elements from AWP, Lean, Design for Manufacturing and Assembly (DfMA), collaborative contracting, and other leading-edge execution methods. A modular project has a different execution methodology than a traditional stick-built execution. Modular projects require a structured process with different sequencing and execution requirements that begin much earlier in the Front-End Planning Stage than a conventional stick-built project. Thus, it is imperative that an advanced planning guide specific to industrial modularization is developed to ensure the success of modular projects.

As identified in the Project Management Institute article “Seven causes of project failure,” inadequate planning is one of the major reasons why projects spin out of control. Companies and projects need to have a consistent methodology for planning and executing projects, and there needs to be a detailed plan developed before the start of any project. [3]

The Modularization Community for Business Advancement (MCBA) has proposed the planning guide as a research opportunity that will provide a timeline of steps and decisions that must be made to ensure that the project management team creates an environment for successful modular project implementation and execution.

Sources:

1 – How Construction Can Emerge Stronger After Coronavirus, McKinsey & Company, May 2020

2 – RT-371 – Onsite versus Offsite Construction – The Impact of Offsite Construction on the Workforce, Conference Presentation, Construction Industry Institute, 2021

3 – Seven causes of project failure, Project Management Institute, Discenza, R. & Forman, J. B., 2007