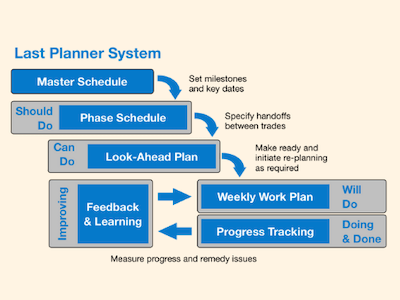

Our method to complete the project was implementing Lean processes, specifically following the Last Planner System (LPS).

How Did AMTS Utilize the Last Planner System?

The Last Planner System is an implementation of a production planning approach to construction projects to enable predictable workflow and rapid learning in the programming, design, construction, and commissioning stages of projects.

AMTS provided value to our client by using the LPS methodology in these five key areas:

- Project start-up and positioning: Consisting of a Pull-Planning process to break down silos and encourage team collaboration by developing a visual representation of the project.

- Construction management: The Pull-Planning was translated into our weekly work planning and daily huddles to continue collaborative planning with all stakeholders. Work was shown and communicated in cross-functional areas and cross-trade discipline.

- Roadblock removal: Constraints that were identified from weekly planning and daily huddles were highlighted and addressed to assure successful delivery.

- Lessons Learned: Continuous learning was achieved by using output data (variances to the plan) to assure improvements in planning an execution.

- Redundancy and waste removed: We followed the pull-planning and weekly work planning process to identify what was actually needed for the project. We connected project team members and challenged the status quo.

AMTS Equipped to Execute Each Project

Following Lean construction principles such as the LPS methodology works best when you have a team in this methodology.

“We bring high-value leadership and execution to every construction project,” says Stephen Poindexter, President, AM Technical Solutions.

“That’s why our long-standing customers in the technology industry continue to rely our team and expertise to complete their projects on-time, within budget, and of the highest quality.”

Contact our team today to start discussing your next Lean construction project.