ISO 14644-1 was first issued in 1999 and Part 2 in 2000. In December of 2015, the International Organization for Standardization (ISO) committee ISO/TC 209, Cleanrooms and Associated Controlled Environments issued the second edition of ISO 14644 parts 1 and 2. Both documents have received significant updates.

ISO 14644-1

The first update to ISO 14644-1 was changing the name to “Classification of air cleanliness by particle concentration” from

the 1999 edition’s “Classification of air cleanliness”. This was done to be more consistent with other parts of ISO 14644.

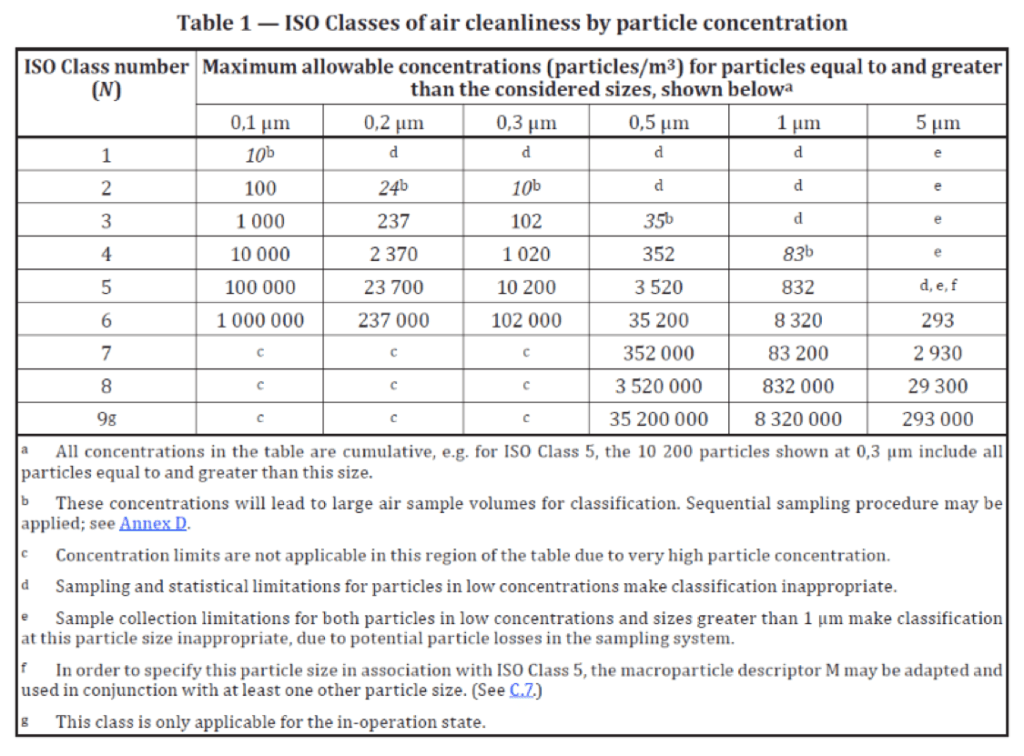

There were also several changes to Table 1. Concentration limits were removed from the following ISO Classes and particle sizes:

- ISO Class 1 at 0.2 µm

- ISO Class 2 at 0.5 µm

- ISO Class 3 at 1.0 µm

- ISO Class 5 at 5.0 µm

Notes were added to the table to give information and instructions about concentration limits that are not defined (see Table 1).

The removal of a particle limit for ISO Class 5 at 5.0 µm was one of the issues that caused the delay in the approval of ISO 14644-1:2015. This was due to the requirements in EU-GMP Annex 11. It was decided that the use of an M descriptor was the proper way to handle the issue.

In Section 5.1 states “At-rest or operational classification may be performed periodically based upon risk assessment of the application, typically on an annual basis”. A note was added “Where the installation is equipped with instrumentation for continuous or frequent monitoring of air cleanliness by particle concentration and other parameters of performance as applicable, the time intervals between classification may be extended provided that the results of the monitoring remain within the specified limits” this was in ISO 14644-2:2000 section 4.2.4 and 4.2.5 but was removed and added to the ISO 14644-1:2015

Annex A Establishment of sampling locations.

This section has the most significant change to the specification. The 1999 Annex A was removed and replaced with a modified version of 1999 Annex B.

In paragraph A.2.2, the requirement for the particle counter to be calibrated to ISO 21501-4 is stated. In the notes for that section it reads, “Some particle counters cannot be calibrated to all of the required tests in ISO 21501-4. If this is the case, record the decision to use the counter in the test report”. Only the newest particle counters can meet the ISO 21501-4. Check with your particle counter manufacturer to see if yours does.

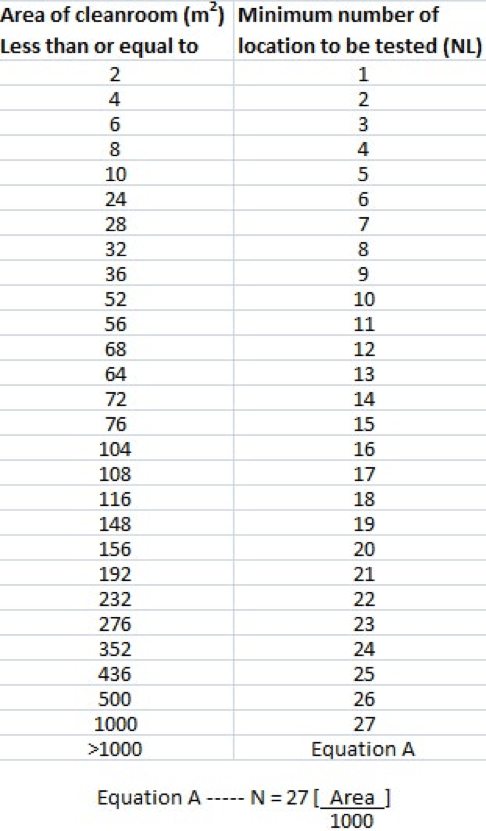

The determination of sample locations for classification in ISO 14644-1:1999 was calculated by using the formula. In the 2015 version the location is derived from table A.1 see below:

The cleanroom is divided into equal grids as is in the 1999 version, but in the 2015 version the location should be representative of the characteristics of the grid. Representative means that features such as cleanroom or clean zone layout, equipment disposition and airflow systems should be considered when selecting sampling locations. If a cleanroom is a non-unidirectional airflow, a location under a HEPA filter may not be representative. Additional sampling locations may be selected for critical locations and must be noted in the report. Additional grids and associated sampling locations may be included to help with dividing the cleanroom into equal parts. If a cleanroom is larger than 1,000 Square Meters (10,764 Square Feet) a formula is used to determine the minimum number of sampling locations. For example a 2,000 square meter cleanroom:

The 2,000 square meter cleanroom would now require a minimum of 54 locations as opposed to a minimum of 45 locations required in the 1999 version. The 2015 version has increased the minimum number of sample locations to insure 95% confidence that at least 90% of the cleanroom does not exceed the class limit. With the increase in sample locations, the requirement for the 95% confidence calculation has been removed from the report. The pass/fail is totaled based on the concentration levels. When one sample location is required, the minimum number of samples has been changed to one from the three samples required in the 1999 version.

Annex B Examples of classification calculations

This annex contains 6 examples of classification calculations with formulas and math.

Annex C Counting and sizing of airborne macroparticles

The 1999 version of Annex C was removed and replaced with a modified version of 1999 Annex E. The Concentrations of ultrafine particles (particles smaller than 0.1 μm) will be addressed in a separate standard to specify air cleanliness by nano-scale particles.

Annex D Sequential sampling procedure

This annex is the same as 1999 Annex F.

Annex E Specification of intermediate decimal cleanliness classes and particle size thresholds

A new table has been added for intermediate decimal classes if required.

Table E.1-Intermediate decimal air cleanliness classes by particle concentration

| Concentration of particles (particles/m3)a | ||||||

| ISO Class number

(N) |

0.1 |

0.2 |

0.3 |

0.5 |

1.0 |

5.0 |

| ISO Class 1.5 | (32)b | d | d | d | d | e |

| ISO Class 2.5 | 316 | (75)b | (32)b | d | d | e |

| ISO Class 3.5 | 3,160 | 748 | 322 | 111 | d | e |

| ISO Class 4.5 | 31,600 | 7,480 | 3,220 | 1,110 | 263 | e |

| ISO Class 5.5 | 316,000 | 74,800 | 32,200 | 11,100 | 2,630 | e |

| ISO Class 6.5 | 3,160,000 | 748,000 | 322,000 | 111,000 | 26,300 | 925 |

| ISO Class 7.5 | c | c | c | 1,110,000 | 263,000 | 9,250 |

| ISO Class 8.5f | c | c | c | 11,100,000 | 2,630,000 | 92,500 |

|

a) All concentrations in the table are cumulative, e.g. for ISO Class 5.5 the 11,100 particles shown at 0.5 µm include particles equal to and greater than this size. b) These concentrations will lead to a large air sample volumes for classification. See Annex D, Sequential sampling procedure. c) Concentrations limits are not applicable in this region of the table due to very high particle concentration. d) Sampling and statistical limitations for particles in low concentrations make classification inappropriate. e) Sample collection limitations for both particles in low concentrations and sizes greater than 1 µm make classification inappropriate, due to potential particle losses in the sampling system. f) This class is only applicable for the in-operation state. |

||||||

Annex F Test instruments

This Annex describes the measuring apparatus that should be used. It’s informative only and should not prevent use of improved apparatuses as they become available.

To make your facility compliant with the new ISO 14644-1 standards, hire a company who understands the changes and has the experience to implement them.