Element 1: HEPA/ULPA Filters

*Updated in August 2018 from original 2014 post date.

One way AMCBP is “Constructing an Intelligent Tomorrow” is through the work of our Cleanroom Performance Solutions group. In this 4-part series, AM Cleanroom Build and Performance’s very own Emil Bordelon, a NEBB Certified Professional, outlines the four main elements of a cleanroom that are considered during the design, certification and maintenance phases.

The 4 elements are:

- HEPA/ ULPA filters

- Airflow

- Cleanroom Classification

- Room Pressure

This week Mr. Bordelon will explain the importance of the proper selection of HEPA and ULPA filters.

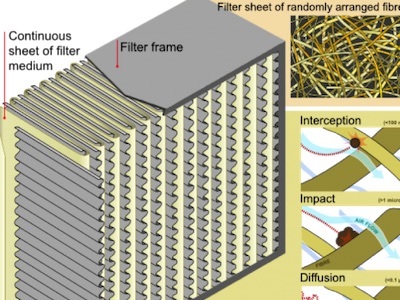

Types of HEPA / ULPA Filters

The first decision that is made during the design phase is the cleanliness class critical for the process or product being manufactured or handled in the cleanroom. To that end there are two types of filters that are used in the different cleanliness classification.

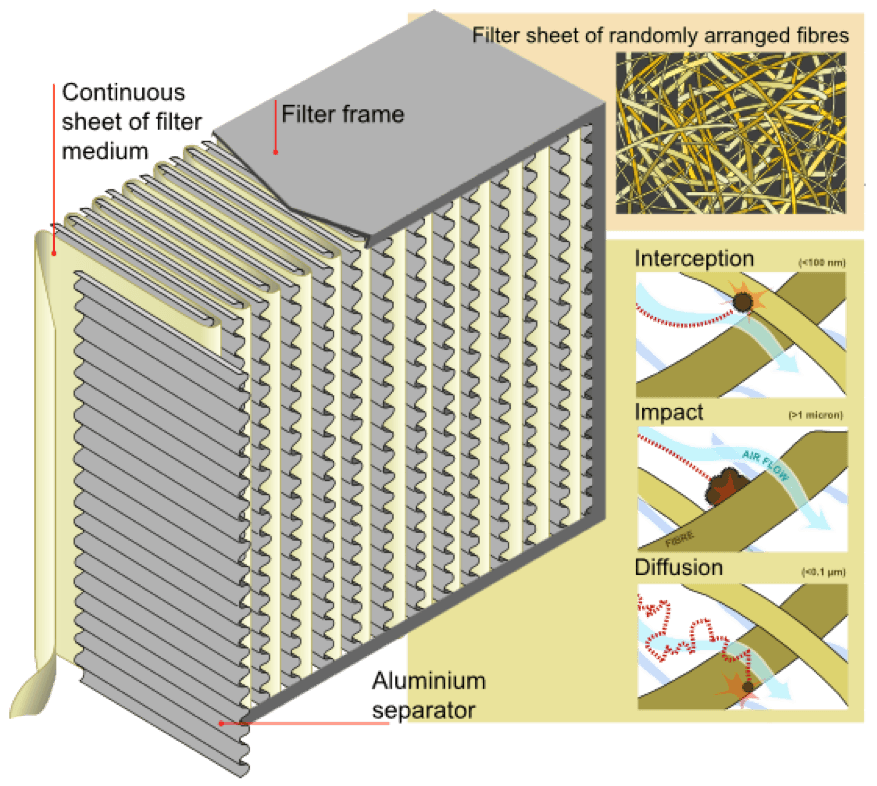

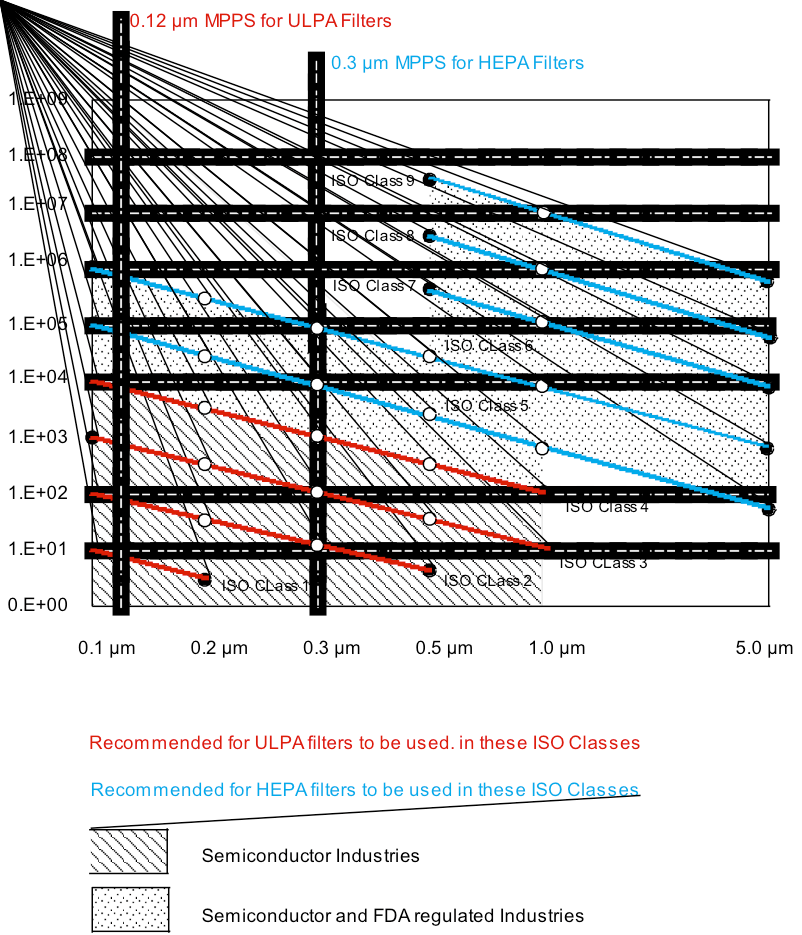

HEPA (High Efficiency Particulate Air) filters have minimum efficiency of 99.97% at 0.3 µm the Most Penetrating Particle Size (MPPS). This type of filter is usually used in ISO Class 5 (100) to ISO Class 8 (100,000). The types of industries that use this type of filter are FDA regulated facilities (drug manufacturers, medical device manufacturers and food and beverage manufacturers), hospital operating rooms and pharmacies and semiconductor (chip manufacturers, circuit board manufacturers, hard drive manufacturers and flash memory manufacturers) and companies that provide materials to the semiconductor companies.

ULPA (Ultra Low Penetration Air) filters have a minimum efficiency of 99.9997 at 0.12 µm MPPS. This type of filter is usually used in ISO Class 4(10) to ISO Class 1. THE ULPA filters are more costly than the HEPA filters which preclude using them in all cleanroom cleanliness classes. This type of filter is used where the smaller size particles are critical to their process or product – mainly in the semiconductor industry.

Most HEPA / ULPA filters media are made of borosilicate microfibers with binding and water proofing agents. These materials tend to off gas. With the new stringent process this off gassing creates difficulties and often contaminates these processes leading to product loss. The industry is moving to low outgassing filters. One type of filter is made of ePFTE (expanded Polytetrafluoroethylene – also called Teflon or Gore-Tex filters), and is becoming increasingly popular. It is corrosion resistant so can be used in highly corrosive areas like a wet benches or chemical manufacturers. It is also water resistant which makes it more suitable with the wet process. Additionally, with lower pressure drop it saves money on utilities and has very low off gassing properties.

Importance of Leak Testing

In the certification phase it is highly recommended that newly installed HEPA / ULPA filters should be leak tested. Every HEPA / ULPA filter is scan tested at the factory but most damages to the HEPA / ULPA filters comes from transportation and installation. Filter leak testing after installing HEPA / ULPA filters is the only way to find these damages. It is an industry recommendation they be tested every 2 years. FDA requires all FDA regulated facilities must be tested every year or at the interval specified in their Current Good Manufacturing Practices (cGMP).

There are two different methods for leak testing HEPA/ ULPA filters. For FDA regulated facilities a photometer is used with an oil base aerosol to challenge the HEPA/ ULPA filter. This is an FDA requirement. For other facilities where the oil aerosol would damage their product or process (especially the semiconductor industry) a particle counter is used with Polystyrene Latex Spheres (PSL). One benefit of using PSL is you can challenge the HEPA/ ULPA filter at the MPPS for the HEPA/ ULPA filter or use a specific particle size that is critical to the process.

HEPA/ ULPA filter leaks are reported in percentages of upstream concentration. A .01% leak is a significant leak and needs to be repaired or the filter replaced. Sometimes the percentage of the leak (the size of the leak) is confused with efficiency of the filter. Filter leak testing is not efficiency testing. Efficiency testing is only performed at the filter manufacturer under strict conditions that cannot be reproduced in the field.

A HEPA / ULPA filter with a significant leak 0.1% and an upstream concentration of 1,000,000 particles at 0.1 µm per cubic foot of air would leak 100 particles at 0.1 µm per cubic feet of air. If you took a 1 Sq. Ft. area directly below the leak and the airflow from the filter was 100 feet per minute the area would be expose to 100 cubic feet of air per minute which would mean 10,000 particles at 0.1 µm per minute or 600,000 particles per hour. As you see even the smallest leak could have a large impact on the process or product.

The Importance of Cleanroom Filter Maintenance

In the maintenance phase the pressure drop of the HEPA/ ULPA filters is critical. As the pressure drop increases the airflow of the HEPA/ ULPA filter starts to be comprised. As the airflow starts dropping off it will reach a point where it is affecting the cleanroom cleanliness class affecting the process or product. It is recommend that the HEPA/ ULPA filter should be change out at double the initial pressure drop or 1 inch of water gauge. One key to prolonging this change out is the pre-filtration of the air going to the HEPA/ ULPA filters. A schedule for the regular change out of the pre-filters should be made. One way to determine if the pre-filters need to change is to measure the pressure drop across the pre-filters. Manufacturers of pre-filters have a max pressure drop for when the pre-filters have to be change. Regular monitoring of the HEPA / ULPA filters pressure drop should be considered. This testing can be included in the cleanroom certification.

For more information about AM Cleanroom Build and Performance, our cleanroom construction, certification and consultation services, please contact us.